Cesar Steve

Suclupe Martinez

Senior Multidisciplinary Designer · Civil, Piping & BIM Automation

Profile

Multidisciplinary designer with ~18 years of experience in civil, mechanical and piping engineering, specialized in BIM-based design and modelling of

road infrastructure, mining platforms and industrial plants. I have worked directly with Peruvian road standards (DG-2014, DG-2018) and international codes such as

ASME B31.3 for process piping and ASTM A36 for steel structures, ensuring that every solution is technically consistent and fully traceable against the applicable standards.

In road engineering, I have developed geometric design of highways (plan, profile, cross-sections), drainage, hydraulic structures, detours and associated structures (bridges, culverts, box culverts), including BIM modelling and construction-sequence simulations for large transportation and mining projects. In piping, I have modelled and documented process systems, city gates, tanks and associated networks under ASME B31.3 criteria. In steel structures, I have been involved in the modelling and quantity take-off of pipe racks, platforms, industrial buildings and port/marine elements.

In parallel to project work, I have 6+ years of experience developing engineering automation solutions using C#/.NET, FastAPI and Python, as well as Windows Forms user interfaces acting as the frontend for internal tools. I have built plugins and services that integrate with Autodesk Civil 3D, Plant 3D and AutoCAD, including APIs for standards queries and automatic generation of design parameters. This combination of project experience and software development allows me to quickly identify critical pain points (quantities, reports, setting-out, multidisciplinary coordination) and turn them into concrete tools that reduce time, errors and rework.

Selected case studies

From DG-2018 automation to large waste dumps, dams and Plant 3D pipelines.

Case Study 1

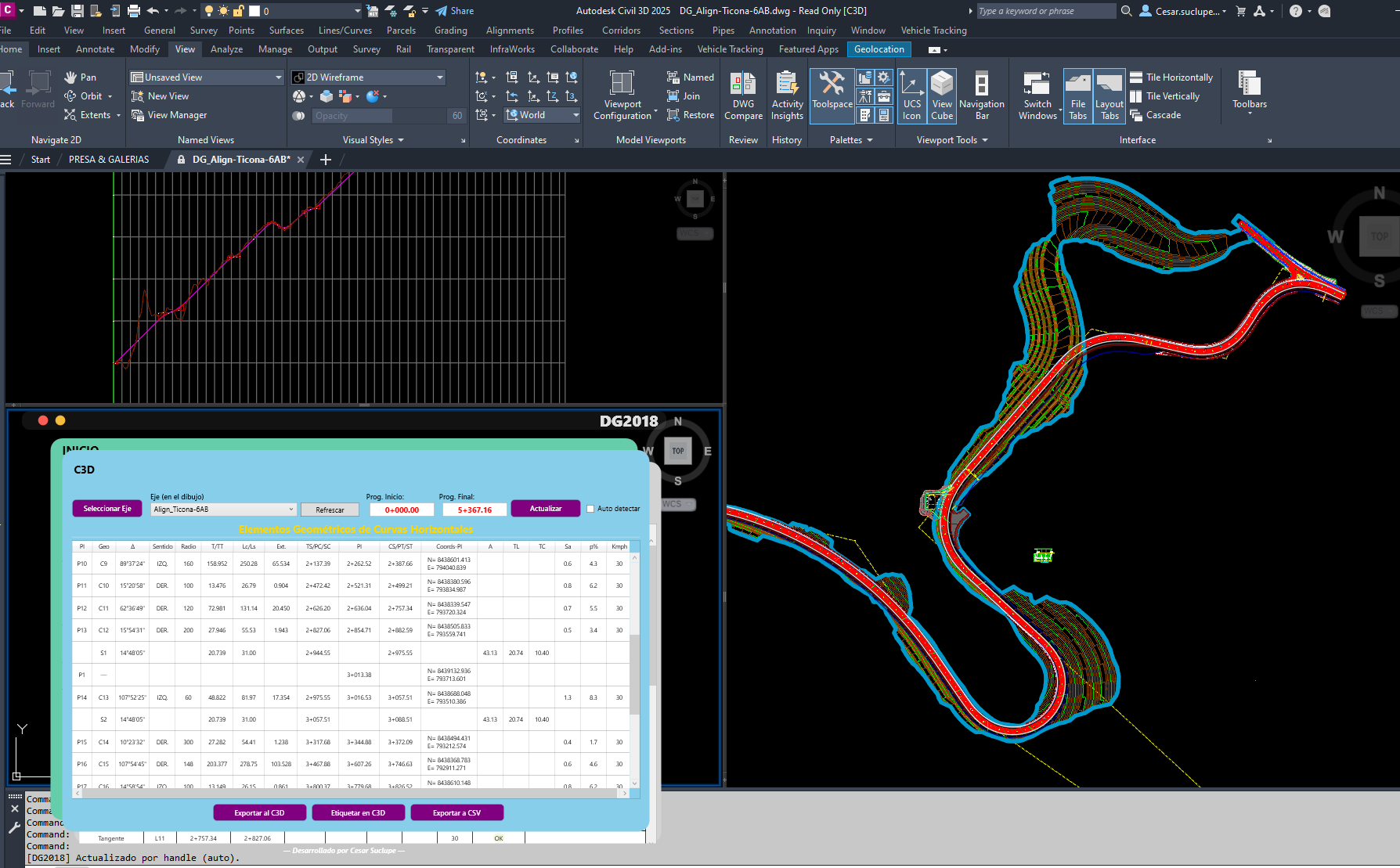

DG-2018 Road Design Automation – CUMBRA

Project

DG-2018 Road Design Automation for Civil 3D

Client / Company

CUMBRA Ingeniería – Internal tool used across mining and road projects

Location / Sector

Peru – Mining access roads and infrastructure

Role

Lead Developer & Senior Civil 3D Designer

Tech & Tools

Autodesk Civil 3D, AutoCAD, C#/.NET, Python, FastAPI, REST APIs, Excel

Challenge

Road alignments for mining projects were being designed in Civil 3D but checked manually in Excel using DG-2018 highway design criteria. This process was slow, error-prone and difficult to standardize across projects and designers. Curve element tables were also generated semi-manually, increasing the risk of inconsistencies between the model, spreadsheets and issued drawings.

What I did

- Designed and implemented a Python + FastAPI backend that encodes the main DG-2018 geometric design rules for road alignments (minimum radii, tangent lengths, speeds, etc.).

- Developed a C#/.NET plugin for Civil 3D that reads alignment geometry directly from the model (tangents, curves, spirals, PIs) and sends it to the DG-2018 API for validation.

- Automated the generation of curve element tables inside Civil 3D, including stations, radii, deflection angles and other data required for staking and verification.

- Implemented a Windows Forms front-end so designers can select alignments, run DG-2018 checks and export standardized reports without leaving the CAD environment.

- Structured the solution so that it can be extended to support additional standards and reused across multiple projects.

Impact

- Reduced road alignment verification time from hours of manual spreadsheet work to a few minutes directly in Civil 3D.

- Eliminated repeated manual transcription between the model and Excel, decreasing the risk of human error in curve parameters and stationing.

- Standardized curve element tables and DG-2018 compliance checks across different designers and projects.

- Created a reusable framework that CUMBRA can leverage for other rule-based design checks, improving overall quality and consistency.

Case Study 2

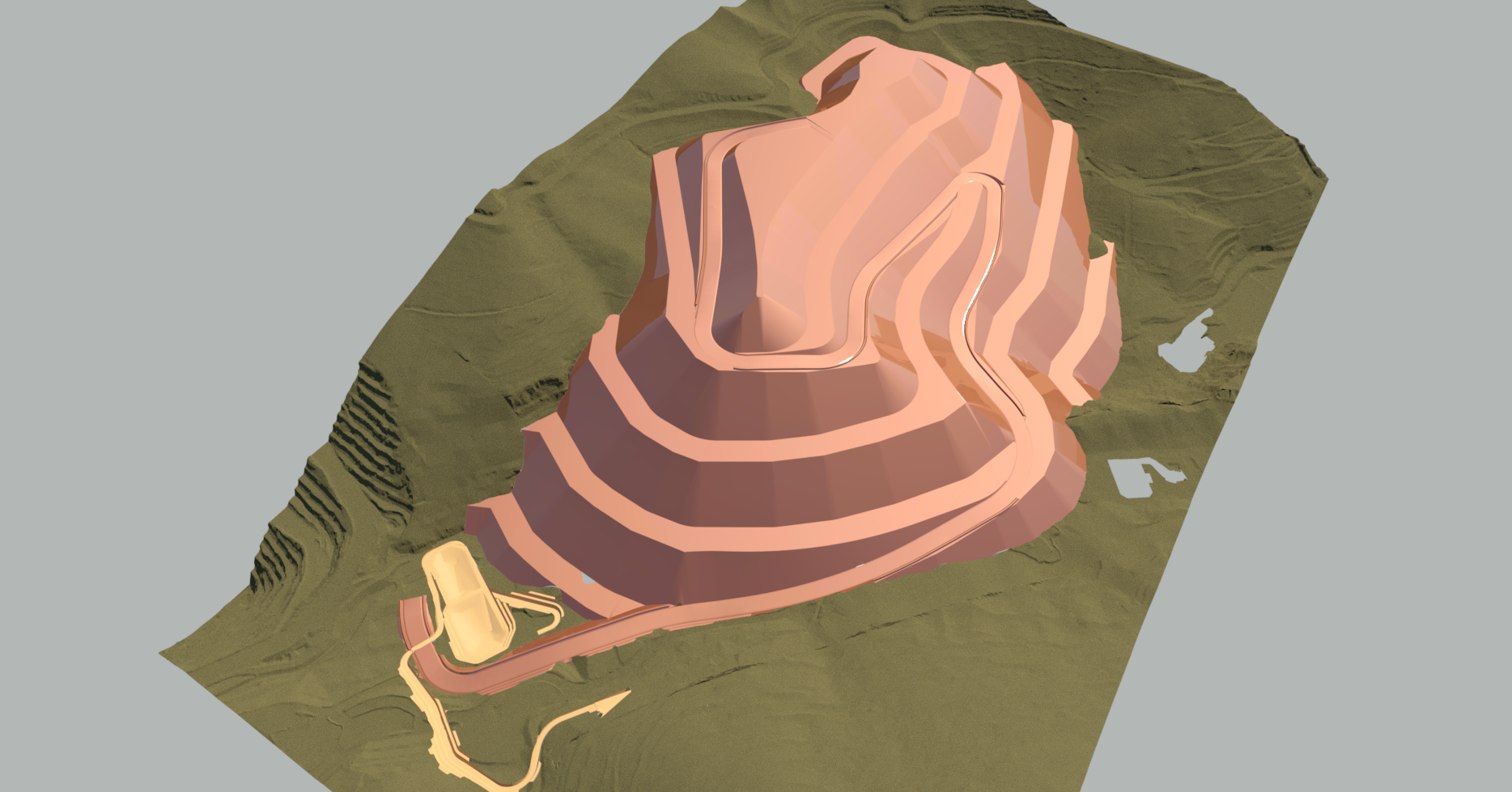

Las Bambas – “Botadero Pionero” (~146 Mm³) – CUMBRA

Project

Las Bambas – “Botadero Pionero” (~146 million m³) and associated earthworks

Client / Company

CUMBRA Ingeniería

Location / Sector

Peru – Large-scale open pit mining

Role

Senior Multidisciplinary Designer (Civil / Earthworks / BIM)

Tech & Tools

Autodesk Civil 3D, AutoCAD, Navisworks Manage, Google Earth, Excel

Challenge

The “Botadero Pionero” waste dump required the management of extremely large volumes of material (~146 million m³), with strict constraints on stability, drainage and operational access. The project also included platforms, haul roads, drainage and sub-drainage systems that needed to be fully coordinated with existing and future mine infrastructure. Documentation had to be consistent and clear for both design review and construction teams.

What I did

- Developed detailed earthwork models in Civil 3D for the Botadero Pionero, including grading, platforms, slopes and access roads.

- Generated and maintained corridor models, cross-sections and volume reports to support design decisions and monthly progress evaluations.

- Designed drainage and sub-drainage solutions (ditches, culverts, box culverts and channels) integrated with waste dump geometry and surrounding terrain.

- Prepared full drawing packages: plan & profile sheets, cross-sections, grading plans and earthwork summaries for construction and internal QA.

- Used Navisworks to coordinate civil models with structural and piping elements, identifying potential clashes at early stages.

- Exported KMZ files and used Google Earth for high-level review of dump footprint, haul roads and interfaces with existing mine layout.

Impact

- Provided a reliable 3D basis for decision-making on one of the largest waste dumps in the operation.

- Improved alignment between design intent, volumes calculations and construction quantities.

- Reduced design iterations by identifying conflicts between earthworks, drainage and other disciplines early in the process.

- Supported project reporting and management with clear, traceable geometry and volume data.

Case Study 3

Chonta Dam – Road Access & Instrumentation – AFRY

Project

Reformulation of the technical dossier for “Regulación de las Aguas del Río Chonta mediante la Presa Chonta”

Client / Company

AFRY (consulting engineer)

Location / Sector

Cajamarca, Peru – Hydropower / water resources / dam engineering

Role

Multidisciplinary Designer – Road Design, Geotechnical Profiles and Instrumentation Layout

Tech & Tools

Autodesk Civil 3D, AutoCAD, Excel, Google Earth

Challenge

The Chonta dam project required a new or improved road connection (tertiary class with tunnel) and a consistent set of civil and geotechnical drawings to support dam design, construction planning and risk analysis. Information had to be coordinated between road design, geology, geotechnics, structures and hydraulic design, while keeping drawings readable and aligned with Peruvian standards.

What I did

- Developed the geometric design of the access/variant road in Civil 3D, including horizontal and vertical alignments, cross-sections and basic earthworks.

- Produced plan & profile sheets, typical and special sections for the road, considering constraints from topography, geology and dam facilities.

- Prepared geological and geotechnical profiles, integrating data from investigations into clear drawings usable by geotechnical and structural teams.

- Worked on layouts for dam instrumentation: location of instruments, galleries and access points for readings, ensuring logical routes and clarity for operation teams.

- Supported the preparation of general arrangement drawings for the dam area, including access roads, ancillary facilities, spoil areas and quarries.

Impact

- Delivered a coherent geometric road design integrated with dam and geotechnical requirements.

- Improved coordination between civil, geotechnical and structural disciplines by providing consistent profiles and sections.

- Clarified the location and arrangement of instrumentation, facilitating long-term monitoring and operations.

- Contributed to a more robust and buildable technical dossier for authorities and the client.

Case Study 4

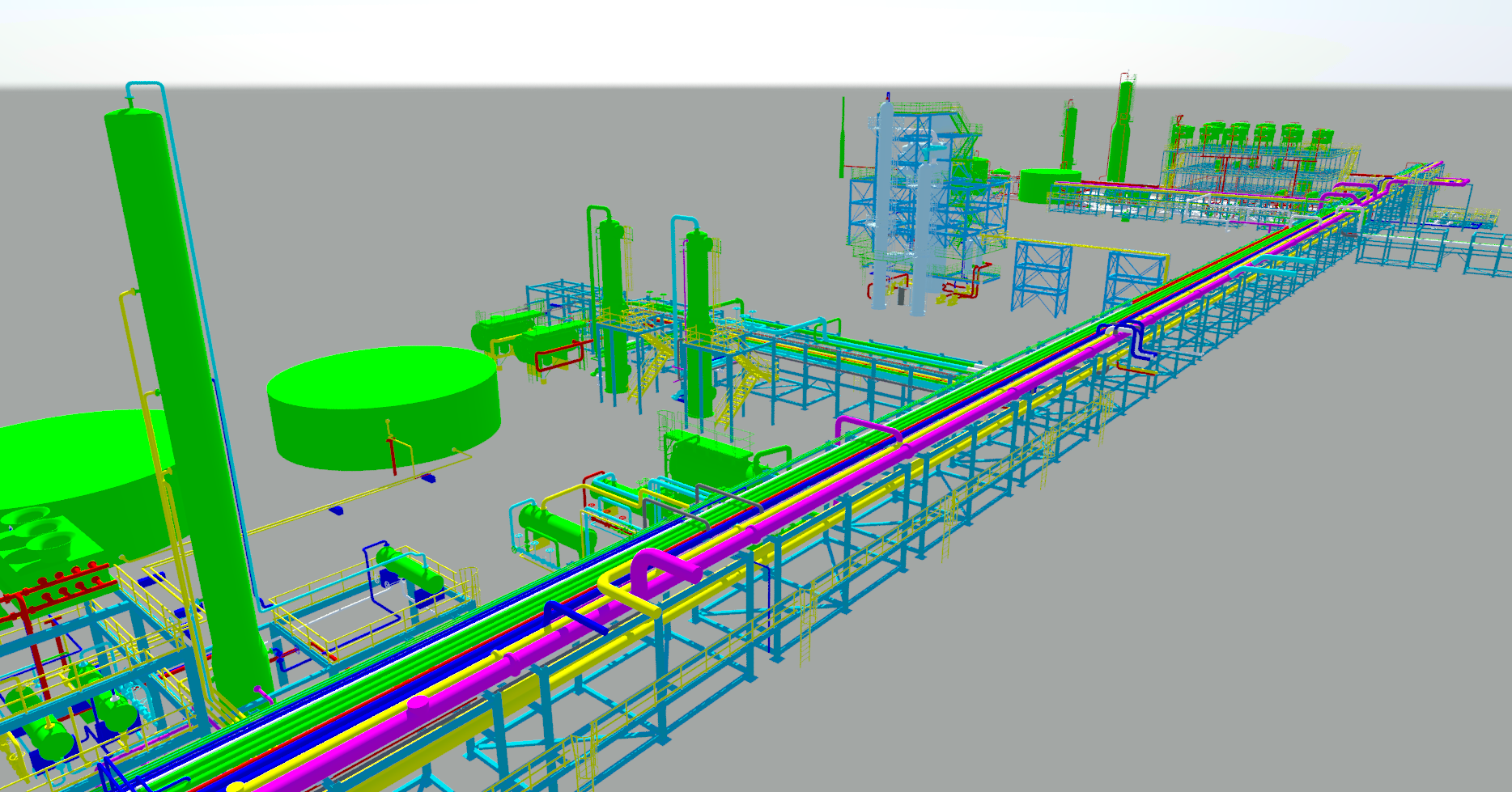

Multi-mine Civil, Structures & Piping Package – WORLEY

Project

Civil and piping design for multiple mining projects (Mina Justa, Escondida, Los Pelambres, Nexa, Minsur, Antamina, Las Bambas, Yanacocha)

Client / Company

WORLEY Ingeniería Perú S.A.

Location / Sector

Peru & Chile – Mining (copper, polymetallic)

Role

Senior Multidisciplinary Designer (Civil / Piping / Structures)

Tech & Tools

Autodesk Civil 3D, AutoCAD, Plant 3D, Navisworks Manage, Advance Steel, Revit, Excel

Challenge

Different mining projects required consistent, high-quality civil and piping deliverables under tight schedules and various client standards. Scope ranged from earthworks and platforms to pipelines, foundations, electrical rooms and pipe racks. Coordinating models and drawings between disciplines and locations (Peru, Chile, Australia teams) was essential to avoid rework during construction.

What I did

- For Mina Justa, acted as lead for earthworks: platforms, access roads, cut/fill models and volume reports in Civil 3D, supporting both design and cost teams.

- For projects such as BHP Escondida and Los Pelambres (Chile), developed civil layouts, excavations and foundations for electrical rooms, transformer pads and duct banks.

- At Nexa (Cajamarquilla) and Minsur (San Germán), designed and modified steel pipe racks, platforms and access walkways, coordinating foundations and steelwork with piping constraints.

- Produced plan views, profiles, cross-sections and detailed drawings for civil works, as well as piping layouts and support details in AutoCAD / Plant 3D.

- Used Navisworks for multidisciplinary coordination (civil, piping, structures, equipment), supporting clash detection and model review sessions.

- Created and maintained Excel-based summaries, quantities and reports for internal checking and client submissions, sometimes fed by Civil 3D outputs or custom scripts.

Impact

- Provided consistent deliverables across a diverse portfolio of mining projects, helping Worley maintain quality and meet client expectations.

- Reduced field clashes and design changes by solving many conflicts at model stage with Navisworks.

- Supported planning and cost control through reliable volumes and quantities derived from Civil 3D models.

- Helped integrate civil, structural and piping design across teams in Peru, Chile and other locations.

Case Study 5

Plant 3D Admin & Isometric Automation – Procure SpA

Project

Autodesk Plant 3D environment administration and isometric automation for mining projects

Client / Company

Servicios Procure SpA (Chile) – remote support

Location / Sector

Chile – Mining / industrial plants

Role

Plant 3D Administrator & CAD/BIM Automation Developer

Tech & Tools

Autodesk Plant 3D, AutoCAD P&ID, C#/.NET, Windows Forms, Excel, Navisworks

Challenge

The client managed several Plant 3D-based projects with different teams and standards. Manual configuration of specs, isometric styles and data consistency checks consumed a lot of time and often led to discrepancies in line data, tags and isometric drawings. They needed a more controlled Plant 3D environment and automation to generate and validate isometrics at scale.

What I did

- Acted as Plant 3D administrator, organizing projects, specs, catalogs and isometric styles to create a coherent and maintainable environment.

- Standardized naming conventions and basic project templates to reduce setup time and inconsistencies between projects.

- Developed C#/.NET utilities with Windows Forms front-ends to:

- Automate batch generation and update of isometric drawings from Plant 3D models.

- Validate line data, tags and key properties before issuing drawings.

- Worked closely with designers and project leads to align the tools with their day-to-day workflows and adjust logic based on feedback.

Impact

- Reduced manual effort in generating and updating isometric drawings, freeing designers to focus on actual design work.

- Improved consistency of tags, line properties and isometric outputs across projects.

- Gave the client a more robust and predictable Plant 3D environment that can be reused in future projects.

- Demonstrated the value of combining Plant 3D expertise with .NET development to solve recurring CAD problems.

Case Study 6

Teaching Autodesk Plant 3D / P&ID – SEMCO CAD

Project

30-hour Autodesk Plant Design Suite training (Plant 3D & AutoCAD P&ID)

Client / Company

SEMCO CAD – Training & CAD Solutions

Location / Sector

Peru – Education / industrial plants

Role

Course Instructor – Autodesk Plant 3D & AutoCAD P&ID

Tech & Tools

Autodesk Plant 3D, AutoCAD P&ID, Navisworks, AutoCAD, real project examples

Challenge

Many technicians and engineers in industrial plant projects needed practical skills in Plant 3D and P&ID, beyond basic commands. The goal was to train them to build usable 3D models, P&IDs, specs and isometrics aligned with real project workflows, not just academic exercises.

What I did

- Designed and delivered a 30-hour course focused on real-world use of AutoCAD Plant 3D and AutoCAD P&ID, with a small introduction to Navisworks.

- Covered P&ID creation, 3D piping modeling, equipment, supports, specs, catalogs, isometric generation and basic reporting.

- Structured the course around a simplified but realistic plant model, so students could understand the full workflow from P&ID to 3D to isometrics and reports.

- Included practical tips from mining and industrial projects (Las Bambas, refineries, gas stations) to connect the software training with field reality.

Impact

- Helped multiple generations of designers and engineers become productive in Plant 3D / P&ID in a short time.

- Strengthened the local ecosystem of Plant 3D users, which indirectly supports companies adopting BIM for industrial plants.

- Reinforced my own expertise by constantly explaining and refining best practices, benefiting my project work as well.

Visual Samples

Selected Drawings & Models

Civil 3D – Road plan & profile with DG-2018 tables

Huacho–Pativilca or Chonta access road – geometric design & replanteo

Earthworks – Botadero Pionero 3D model

Platforms, slopes, drainage and haul roads – Las Bambas (CUMBRA)

Plant 3D – Piping layout & isometrics

Gas station, process area or pipeline project – Worley / Procure SpA